The manufacturing industry has entered an important moment of transformation and upgrading, and more and more factories begin to use machine replacement to enhance enterprise competitiveness. Industrial robots free human labor from harsh working conditions and maximize production efficiency in factories. Therefore, the application space of industrial robots is further opened, from automobile manufacturing to 3C electronics, food packaging, logistics and other fields, the use of industrial robots is growing, from 240,000 units in 2015 sales to 381,000 in 2017, is expected to reach 630,000 in 2021.

The food industry is a very large part of the manufacturing sector and an important market for robotics applications. In recent years, the market environment of food manufacturing industry is developing new changes. In the context of the rapid development of e-commerce, the order demand is growing, and customers require more efficient and flexible packaging production, enterprises in the increase of capacity at the same time to ensure quality. In addition, personalized needs pose new challenges for enterprises. In response, more and more factories are using industrial robots.

The use of industrial robots will transform the food industry, eventually moving towards a production model of intelligent manufacturing, capable of filling customer orders in a few hours. At present, industrial robots mainly carry out food processing, sorting, palletizing and packaging tasks, and bring many potential benefits, including improving production efficiency, reducing material loss, ensuring product consistency and shortening delivery, and so on. The new production mode has high flexibility to meet the production needs of small batch personalized products.

Replacing machines with people creates new advantages for enterprises

Compared with traditional human production models, robotic automation solutions lead to higher productivity, making production services more economical and efficient. Moreover, with the gradual disappearance of demographic dividend, labor costs will become more and more expensive. Factories will give priority to robots to perform production tasks, not only to reduce costs, but also to reduce the chance of industrial injury, improve production efficiency and increase corporate profits.

Food safety and hygiene requirements are very strict, traditional human way may bring food pollution, but the use of robots can be a good solution to this problem, automatic food processing process is not affected by human. Robots in the food industry have been treated with hot water and disinfection, which can well avoid the spread of bacteria and ensure food safety.

Robots can operate normally in extremely cold, high temperature and even lack of oxygen, which is not suitable for human beings. And some food manufacturing may require freezing temperatures, so the use of robots could improve the quality of food. In addition, the higher accuracy of the robot can not only ensure the consistency of the product, but also reduce the waste of ingredients.

In addition, the use of robots can also improve the safety of workers. Food processing can ensure the safety of workers by using sharp and dangerous equipment. These tasks in dangerous environments can be taken over by robots without the involvement of workers. It is also the repetitive tasks that are uncomfortable for humans, and robots would be better suited to these roles because they would not get bored or tired.

Application scenario of robot in food manufacturing industry

In many places in the food industry can use robots, robots in the food industry is the main packaging, palletizing, sorting, processing and other processes, which palletizing robot is the use of the largest part, almost occupies half of the share of the whole food manufacturing robot.

Palletizing refers to stacking products with basically the same shape according to certain requirements, which is often seen in production lines, warehouses and other scenes. For some heavy items, the use of human stacking is not appropriate, easy to cause sprain. Robots can quickly and efficiently complete the stacking of weight products, which has become the most common application in the food industry. At present, domestic Yili, Wahaha and other food and beverage enterprises are using palletizing robots to improve the efficiency of production.

In addition to palletizing, food packaging is also a relatively wide range of robot applications. With the development of food refinement and diversification, the demand for small batch diversified packaging is becoming more and more obvious. Industrial robots have high flexibility, can realize the same packaging line for a variety of sizes and shapes of products packaging, only need to adjust the parameters and end tools, can complete the new task. As a result, industrial robots are favored by food packaging companies.

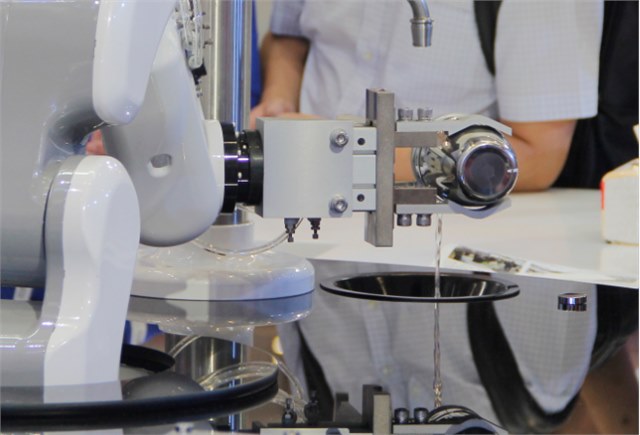

There are many applications of industrial robots in the food industry, such as food processing, where robots can replace workers for cutting, cutting, cleaning, grinding and other work. Combined with the Internet of Things sensor and artificial intelligence technology, robots can be more accurate than people and can meet increasingly high process requirements. There is food sorting. Through machine vision recognition technology, the robot can select and classify food materials, which not only saves manpower, but also improves efficiency.